Changeover time reduction

✔ Realistic planned changeover times

✔ Changeover time reduction

✔ Motivated employees

✔ Smart scheduling

✔ Realistic planned changeover times

✔ Changeover time reduction

✔ Motivated employees

✔ Smart scheduling

Converting a line from one product to another is one of the biggest OEE losses. Due to the large number of possible transitions, it is impracticable to set a changeover time for each product transition in advance. The changeover time reduction module does it in a more dynamic way, it calculates a planned changeover time based on product properties and machine choice. By presenting the planned time as a countdown timer, which starts with the order change and stops as soon as the first good products are registered, everyone knows exactly whether and to what extent the conversion was achieved within the set time.

The changeover time reduction module provides all the tools to reduce the changeover time as much as possible:

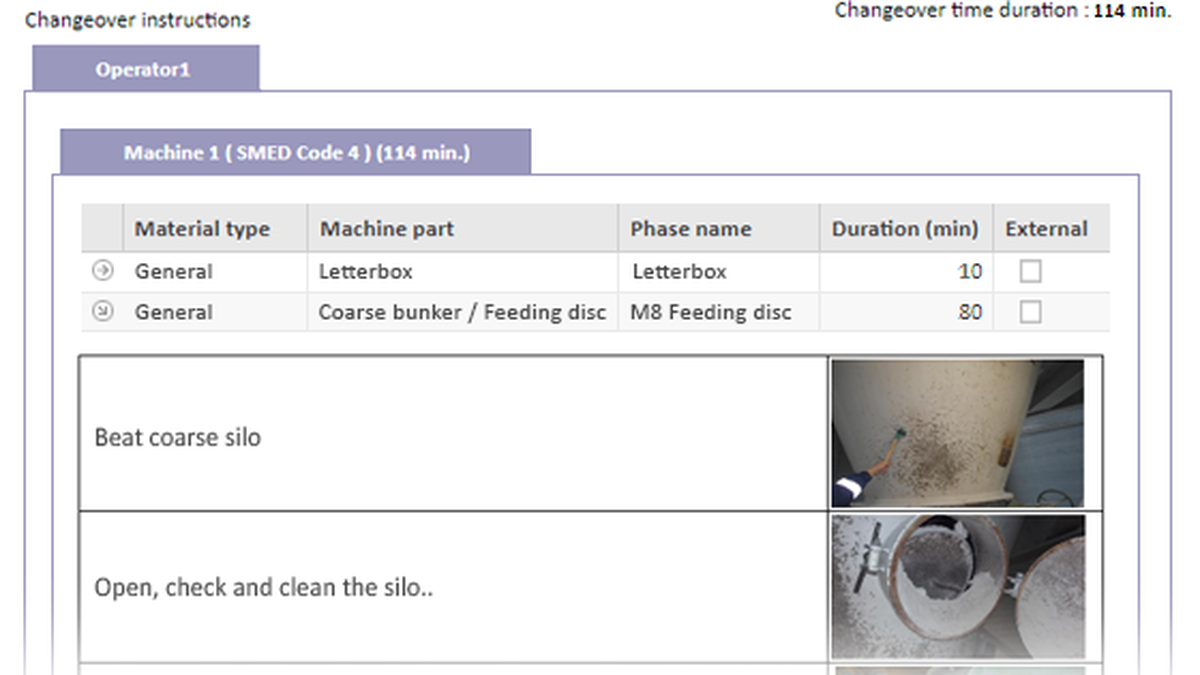

Changeover instructions with text, photos and/or videos

Checklist for checking (quality control)

Early indication of changeover time (technical service)

Early indication of the required materials and tools (logistics service)

Button for requesting extra assistance

Employees can indicate all preparations for a conversion that have already been carried out in the checklist.

SMED-Method is a powerful LEAN tool to reducing changeover times in processes and machines.

Thanks to awareness, machine adaptation, training and/or better coordination, the loss due to changeovers will be drastically reduced. Something that is clearly reflected in the changeover time overview report. With handy tools you can easily adjust the basic data for the calculation of the planned changeover times. As a result of this continuous process, the planned changeover times always correspond to reality.

Planned changeover time falls into the category of planned stoppages for production employees and therefore has no influence on the OEE result for them. On the other hand, there is an overrun on the planned changeover time.

This is particularly important for the involvement and motivation of the employees in the OEE improvement process. Thanks to the changeover module, it is still possible for operators to achieve an OEE score of 100% with frequent or long-term changes!

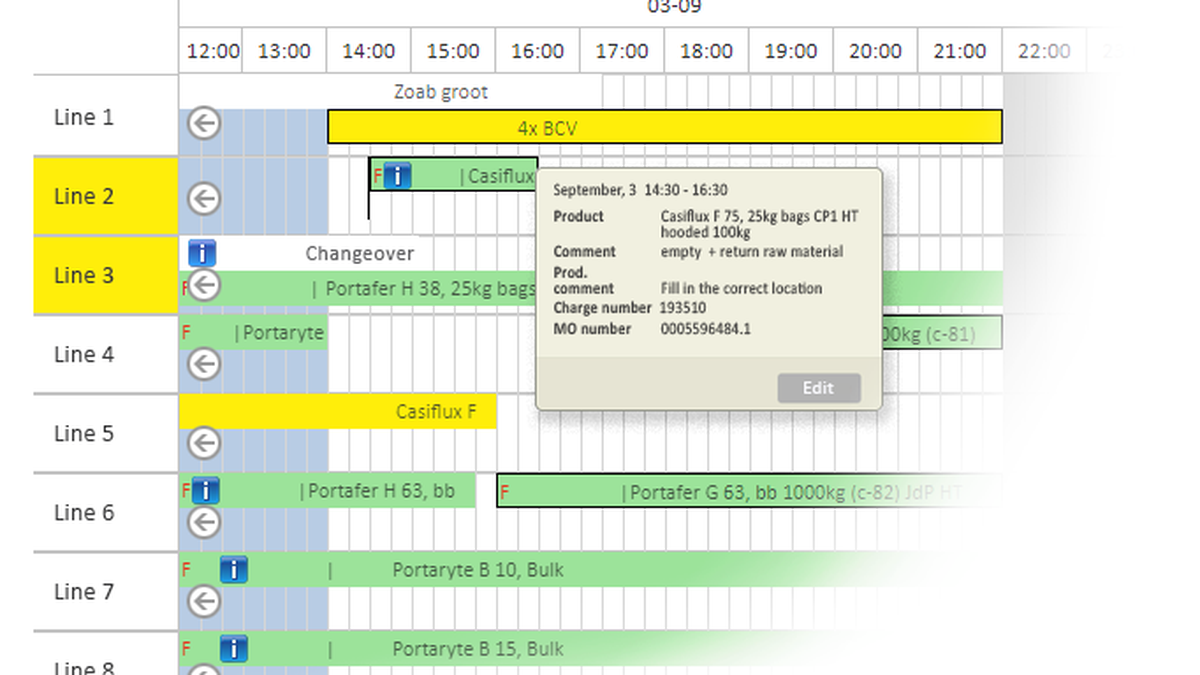

The calculated planned changeover time also forms an important input for the production scheduling board, which includes the planned changeover time in the lead time of a production order. By changing the order of production orders in the planning table, you can minimize the total changeover time.

We are currently working on functionality that automates this, but given the extremely large number of options, it is difficult to calculate quickly.

Do you want to implement changeover reduction steps? Feel free to ask our experts for more information or request a demo right away and experience it for yourself! Contact us, call +31 76 5156572 or send an email to info@agilitec.nl.

Request a demo