OEE: How to calculate and improve

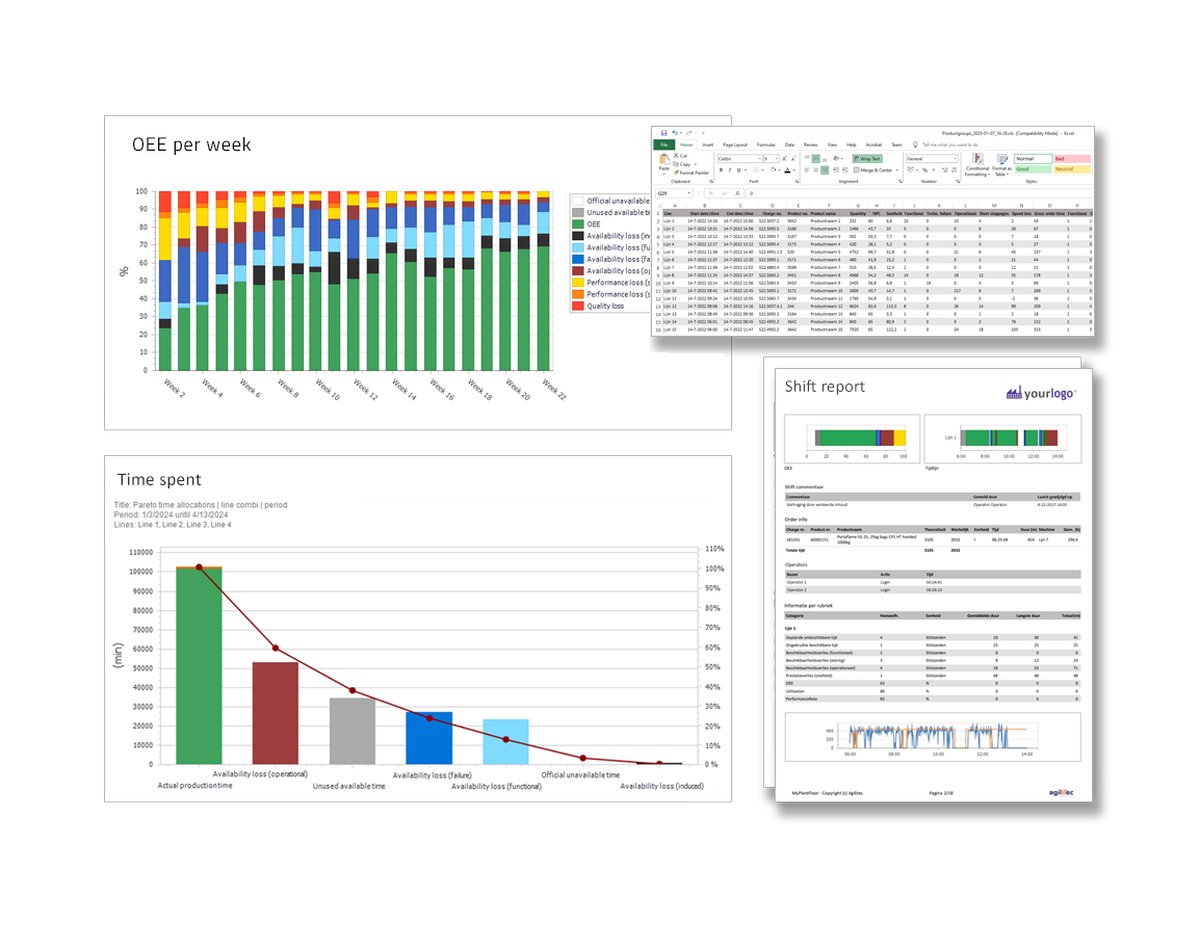

Would you like to have your company's OEE calculated and, if necessary, improved? We would be happy to provide you with more information about the formula for calculating your OEE and help you with your OEE-measurement. Agilitec is a company specialized in software solutions for companies. The OEE-System, MyPlantFloor, allows you to perform realtime OEE registration.

)

)

)