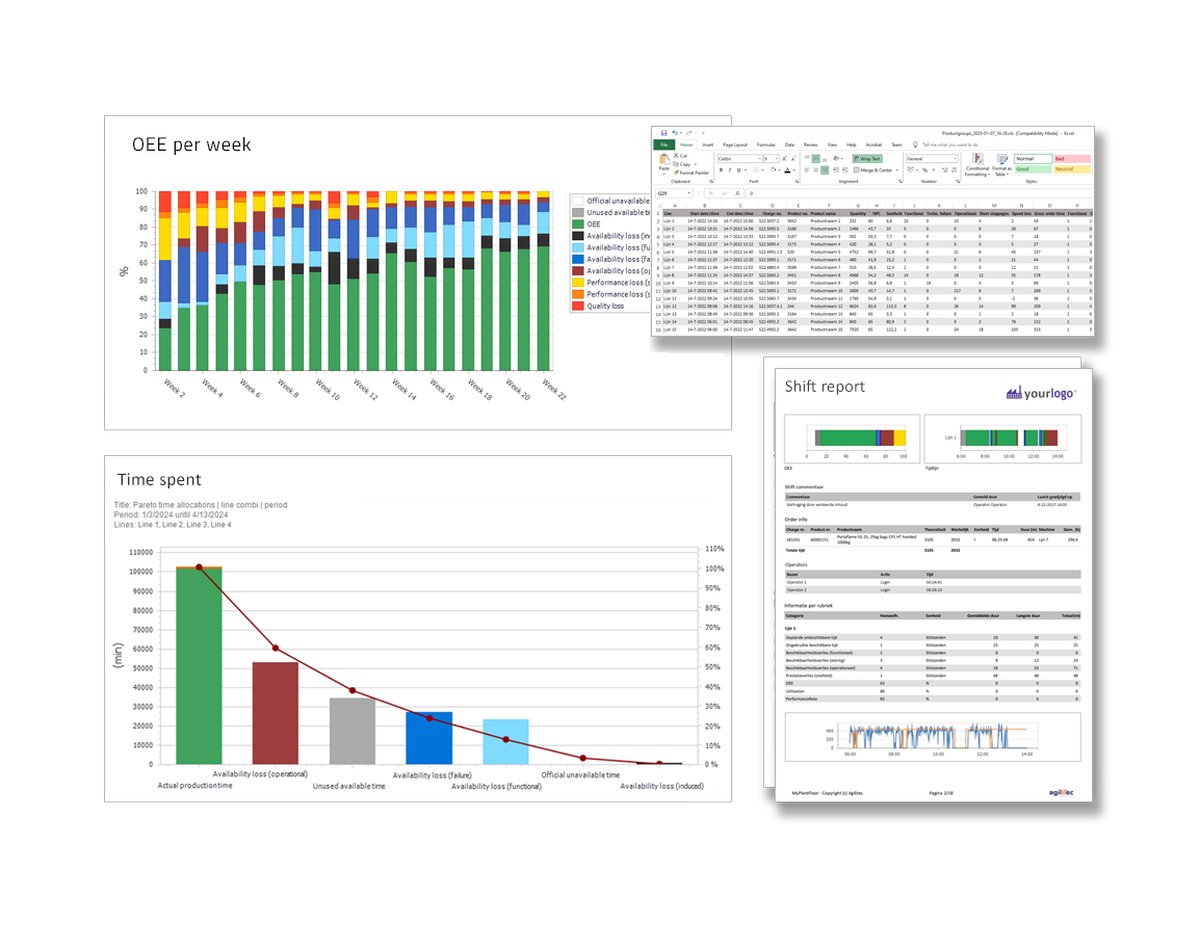

Production orders + OEE

The MyPlantFloor production order/OEE application offers all the essential functionalities for an efficient production floor. The user interface is fully web-based in multiple languages and the application can be used both on-premise and in the cloud.