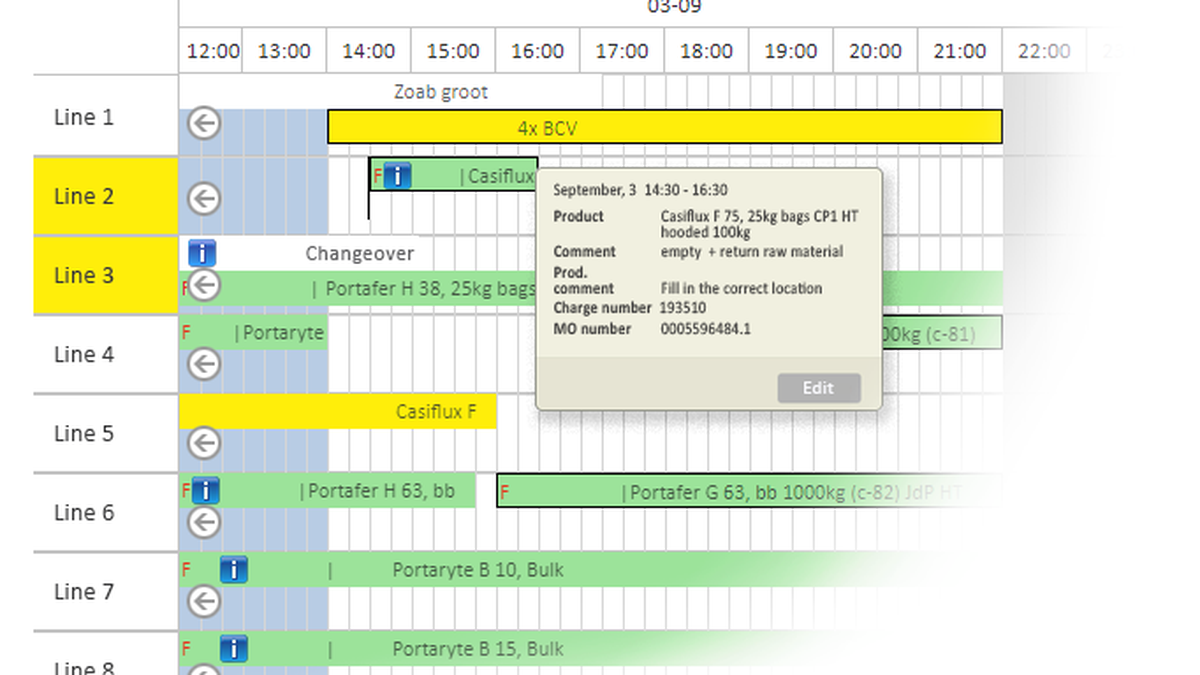

Production scheduling board

➔ Graphical assignment of orders to machines and optimal sequencing

➔ Current graphical overview of the planning thanks to real-time feedback

➔ Presentation also as a table with drag and drop possibility

➔ Graphical assignment of orders to machines and optimal sequencing

➔ Current graphical overview of the planning thanks to real-time feedback

➔ Presentation also as a table with drag and drop possibility

The production scheduling board module (or finite capacity scheduling) always offers you a complete, real-time overview of the current production planning and feasibility of agreed delivery times. Authorized users can easily adjust the production schedule by dragging order bars and/or adding planned activities to the schedule. The result is a true graphical overview of order bars with a clear indication of whether the stated delivery time is at risk.

MyPlantFloor imports the (raw) production planning into the real-time production scheduling board via an ERP link. Depending on the setting, the imported production orders are automatically or not distributed among the machines and put in the correct order. Finite capacity scheduling determines the total lead time of the remaining part of all planned production orders (read: length of the order bars) with the corresponding product/machine standard speed, taking into account planned downtimes such as changeovers, breaks, planned shifts, etc…. The entire production planning is calculated again and again in the background with the most current data regarding the completed number of products from the MyPlantFloor OEE system. The result is a planning that always corresponds to reality.

)

For a better overview, for example in the case of large numbers of short-term orders, there is the option of presenting the production scheduling board in the form of a table. Here, too, you can adjust the order by dragging the rows. Just like in the production scheduling board, a complete recalculation of lead times will take place here after each change, and you can see from the color of the row whether the set delivery time is at risk.

With a mouse click on a bar or line, all details of an order appear, which can also be modified here for an authorized user. This includes order comments, raw material silo no., planned number of operators, order size and much more. All functions belong to the production scheduling board.

MyPlantFloor production planning software offers an intuitive production scheduling board that allows your production planner to easily manage, optimize and monitor production orders in real time. With a production planning tool, logistics, scheduling, quality control and maintenance can run more efficiently, work better together and anticipate each other. Ensure higher customer satisfaction, increased profitability and more flexibility in the production process.

Experience for yourself how the software can take your production planning to the next level. Request a free demo or no-obligation quote today and discover the benefits of the Finite capacity scheduling.

Request a demo